The graphene additive for concrete:

a revolutionary thermal insulator in construction

In recent years, the construction industry is looking formward to improve the properties of mortar and concrete, to increase their durability, especially in structures exposed to aggressive or extreme environments. Among the properties that are sought to improve, is the resistance to compression, the resistance to compression tension, as well as to reduce cracking. With the increase in the volume of concrete in civil engineering projects, more attention has been paid to the thermal cracks that occur. Experimentation has shown that during the hydration process of the mortar and/or concrete, heat is generated due to the exothermic reactions that occur. Poor heat dissipation causes a gradient between the interior of the mass and its surface, which generates internal stresses and can lead to cracking or thermal cracking in the concrete.

Nowadays, graphene oxide (GO), a graphene precursor material, has attracted a lot of attention because it is an insulating material, with low thermal property and has extraordinary mechanical properties. GO has a large surface area (2600 m2/g) and the presence of oxygenated groups gives it unique properties that make it easily dispersed in water, making it an ideal nanomaterial for the development of concrete additives.

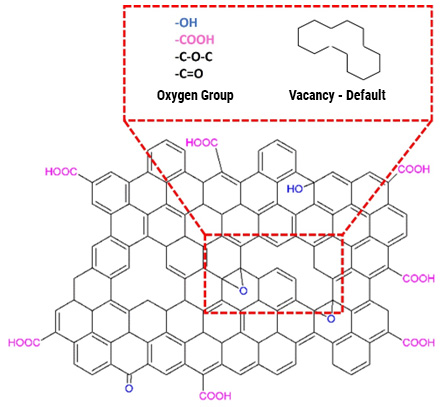

Although the mechanical properties of cement-based compounds and structures are important in building infrastructure, the thermal insulation property is very important to reduce energy consumption for air conditioning and heating in buildings. Therefore, GO is a good candidate due to its low thermal conductivity properties. Thermal conductivity is defined as the ability of a material to transfer heat. It is the phenomenon by which heat spreads from high-temperature areas (warmer) to colder areas within the material. In the case of GO, the presence of holes and functional groups on the GO surface cause local stress or instability, resulting in a reduction in thermal conductivity of up to 2 to 3 orders of magnitude (<100 W/m-K). In the GO, the propagation of heat flux occurs in the vacant regions (voids) and in the oxygenated functional groups of the GO surface (Figure 1). When a heat flux attempts to traverse the GO through some defect or vacancy, the heat flux not only propagates out of plane, but also disturbs the heat flux around the basal plane gap.

and randomly distributed oxygenated functional groups.

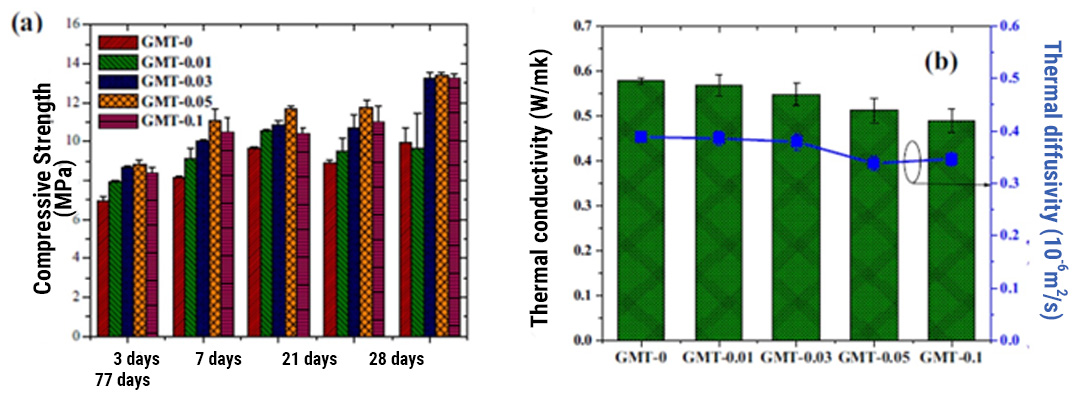

Recent investigations have reported the improvement of the thermal insulation properties of cement-based composite materials by adding different concentrations of GO, as well as the effect of GO on increasing compressive strength and greater impermeability to chloride ions. and water in concrete. The incorporation of GO decreased microcracking, the porosity of the material (decreases the volume of pores) and improved compaction. GO sheets become a barrier to crack propagation, which improves mechanical properties. The compressive strength of the specimens of the compounds with GO concentrations of 0.05% by weight increased by up to 18.7% and 13.7% at a curing age of 7 and 28 days, respectively. In the case of the evaluations of the thermal properties of the compounds, the thermal conductivity was 0.578 W/m K for the specimen without GO (control) and 0.490 W/m K for the compound with 0.1 % by weight of GO, while that the thermal diffusivity values oscillate between 0.38× 10-6 and 0.33× 10-6 m2/s (Figure 2). Thermal conductivity decreases with increasing GO content due to low conductivity or excellent insulating effect of GO sheets and good interactions between mortar and GO sheets. Generally, material with thermal conductivity values of less than 0.250 W/m K is known as a thermal insulator. Therefore, the thermal insulation of the mortar is improved in the compounds with the incorporation of GO.

Energeia -Graphenemex® developed and sells an admixture for concrete with graphene oxide (Graphenergy Construction). A nanotechnological additive that improves mechanical resistance, impermeability and provides an antimicrobial effect to any cement-based material. The additive can also manage to reduce the final number of pores in the set product, which translates into a more compact product and greater impermeability to the passage of water, improving the protection against corrosion of steel cores in concrete.

The thermal insulation property of the additive can achieve a reduction in the temperature of concrete-based structures, infrastructure, or buildings to a more comfortable temperature inside (up to 3 °C), reducing energy consumption for air conditioning and/or or heating in buildings.

References

- Janjaroen, Khammahong. The Mechanical and Thermal Properties of Cement CAST Mortar/Graphene Oxide Composites MaterialsInt J Concr Struct Mater (2022).

- Yi Yang, Jing Cao y col.Thermal Conductivity of Defective Graphene Oxide: A Molecular Dynamic Study. Molecules 2019, 24, 1103.

- Guojian Jing, Zhengmao Ye y col. Introducing reduced graphene oxide to enhance the thermal properties of cement composites. Cement and Concrete Composites 109 (2020) 103559.