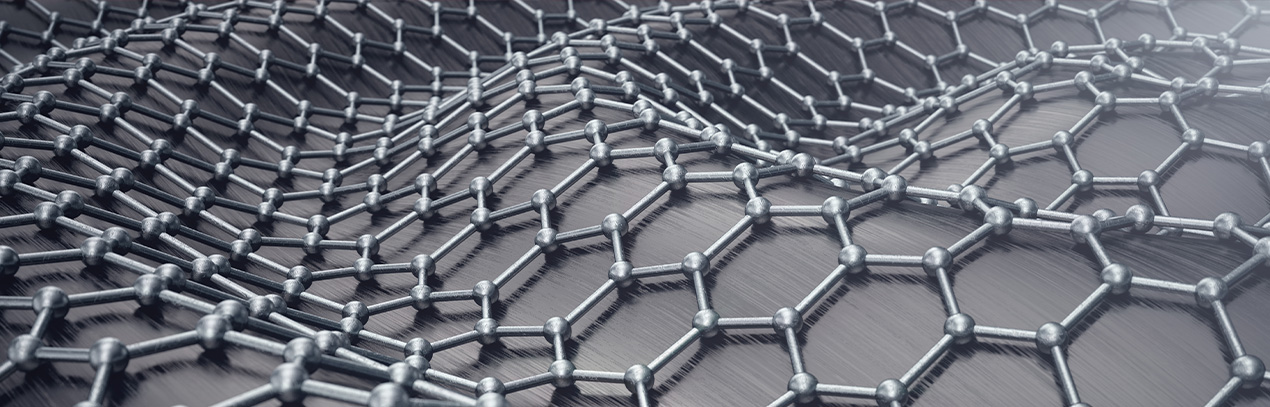

THE WORLD OF GRAPHENE

Discover the potential of masterbatches in our video section

BLOG

Conductivity and Control: Graphene in the Evolution of Antistatic Materials

Graphene and Bioplastics: Innovation for Enhanced Sustainability

Biocompatibility and Biodegradability of Graphene: Advances and Scientific Evidence

RESEARCH

We share with you some of the multiple investigations that are being carried out worldwide on the benefits of graphene masterbatches.

On the graphene nanoplatelets reinforcement of extruded high density polyethylene DOWNLOAD