Performance of Reinforced Concrete with Polymeric Macrofibers and Graphene Oxide:

Results Report Graphenergy® Construction

Polymeric macrofibers are small filaments of strong synthetic material dispersed throughout the concrete mix to reinforce it from within. Their random distribution creates a discontinuous and homogeneous three-dimensional reinforcement effect that enhances the concrete’s toughness and ductility at every point of the structure.

The materials commonly used for the manufacture of this type of product include polypropylene, polyethylene, polyester, or nylon in different gauges or dimensions. These are highly effective for the reinforcement of pavements and roads, slabs, precast elements, shotcrete, and in some cases, may even substitute welded wire mesh. Given the wide variety of products, it is important to seek proper advice before use and to consider that macrofibers do not always increase the compressive or flexural strength of concrete, as they are mainly used for microcrack control. Therefore, they are not intended as a full replacement for structural reinforcement such as steel.

The Mexican company Energeia–Graphenemex®, through its polymer division, integrated the multifunctionality of graphene oxide to launch Graphenergy® Polymeric Macrofibers in order to enhance concrete performance under intense stresses.

Graphenergy® polymeric macrofibers represent an innovation in secondary three-dimensional reinforcement for concrete thanks to the integration of polymers and graphene oxide in their formulation. Unlike conventional fibers, the nanotechnology-based design and wavy surface of these macrofibers significantly improve their performance within the concrete.

“Graphene oxide is one of the most promising materials for enhancing the properties of a wide range of polymers. It consists of graphene—or pure carbon—sheets stabilized with oxygen-containing groups, resulting in a versatile structure that is water-compatible, adherent to cement crystals, and easily combinable with other compounds to design materials with new or improved properties.”

Why use graphene oxide in the production of synthetic macrofibers?

- Enhances the mechanical properties of polymers, thereby increasing the resistance of each fiber under loads.

- Improves fiber compatibility with concrete, resulting in excellent dispersion within fresh concrete.

- Generates a better fiber–cement interface, improving fiber anchorage within hardened concrete.

Evidence-Based Science

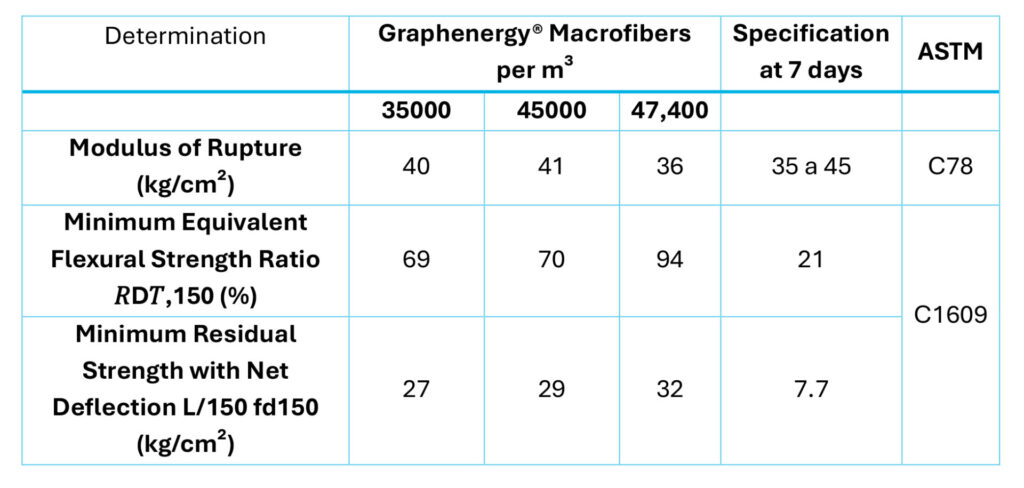

As evidence of the benefits that synthetic macrofibers with graphene oxide offer concrete, the following results are presented from a study conducted to analyze the performance of concrete reinforced with different dosages of Graphenergy® Macrofibers at 7 days.

It is important to note that the standards and limits applied were defined according to the requirements of a specific project; therefore, the reported information is for reference purposes only.

How is fiber-reinforced concrete evaluated?

The most relevant tests focus on determining how fibers improve the strength and toughness of concrete, particularly after cracking occurs.

- ASTM C78 is used to determine the flexural strength of plain concrete (without fibers), measuring how much force concrete can withstand in bending before breaking.

- ASTM C1609 is used to evaluate fiber-reinforced concrete, specifically its residual strength once the first crack appears, as well as its behavior under further loading or tensile forces.

Materials Used

The materials were selected in compliance with applicable standards according to the mix design and project limits, including: sand, gravel, Type II cement, water, a water-reducing admixture, and the key variable of this study: Graphenergy® synthetic macrofibers at a dosage of 35,000 to 47,000 fibers per m³ of concrete.

Results Table

Interpretation

Modulus of Rupture

Before the appearance of the first crack, concrete dosed with Graphenergy® macrofibers resisted between 36 and 41 kg/cm², meeting the specification for reasonably strong flexural concrete. It is worth noting that this test is relatively independent of fiber presence, as it depends more directly on cement paste, aggregates, and curing. As expected, the fibers did not significantly influence these results. However, the fact that the specification was met is an indication of proper fiber distribution in the mix.

Minimum Equivalent Flexural Strength Ratio 𝑅D𝑇,150

This determination highlights the true contribution of macrofibers, as it measures the residual strength of concrete after cracking. According to specifications, concrete should retain at least 21% of its original strength. Remarkably, Graphenergy® macrofibers enabled the concrete to retain between 69% and 94%, depending on fiber dosage. This demonstrates that the fibers continue to work effectively even after cracking.

Minimum Residual Strength with Net Deflection L/150 fd150

This result reflects the post-cracking behavior of concrete in terms of crack control. The results shown in the table confirm the added value of macrofibers in improving early-age resistance, offering performance more than 300% above the specification (7.7 kg/cm²).

Conclusion

The study demonstrates that concrete reinforced with Graphenergy® Macrofibers not only meets but significantly exceeds project specifications. While not all properties show a linear correlation between fiber dosage and strength—such as modulus of rupture—the results clearly show substantial improvements in post-cracking capacity and toughness. These macrofibers emerge as a novel, highly recommended alternative for concrete reinforcement in applications subjected to impacts, cyclic loads, or where ductility is essential.

Prepared by: EF/DHS