Biocompatibility and Biodegradability of Graphene:

Advances and Scientific Evidence

Graphene is widely recognized for its exceptional properties and its potential to revolutionize various industries. However, as a relatively recent technology with emerging applications, concerns have arisen regarding its impact on human health and the environment. Therefore, it is essential to analyze scientific studies that have evaluated its biocompatibility and biodegradability, providing evidence of its safety and behavior in different biological systems.

Biocompatibility: Defined as the absence of allergic or immune adverse reactions to a material in the body

Over the past decade, multiple studies have demonstrated that graphene and its derivatives can be biocompatible under certain conditions. Research on its interaction with blood, cell differentiation, kidney function, neuronal activation, and bone regeneration has yielded positive results. The following key findings stand out:

2012 – Compatibility with blood and macrophage response. The nanotoxicity of graphene on macrophages was evaluated based on its effects on metabolic activity, membrane integrity, oxidative stress induction, hemolysis, platelet activation and aggregation, coagulation cascade, cytokine induction, and immune cell activation and suppression.

Results indicated that while graphene does interact with macrophages, toxicity is significantly reduced through surface functionalization. Regarding blood compatibility, both functionalized and non-functionalized graphene exhibited excellent compatibility with red blood cells, platelets, and plasma coagulation pathways, with minimal alteration in cytokine expression by human peripheral blood mononuclear cells. Additionally, no premature immune cell activation or suppression was observed up to a relatively high concentration of graphene (75 μg mL⁻¹) after 72 hours of in vitro incubation.

Conclusion: Possible graphene toxicity can be easily avoided through surface functionalization.

A. Sasidharan, et. al., Hemocompatibility and Macrophage Response of Pristine and Functionalized Graphene, Small, 2012, 8, 1251

2014- Cardiac cell differentiation. The effect of graphene on the cardiomyogenic differentiation of human embryonic stem cells (hESCs) was analyzed. Graphene was synthesized via CVD and deposited on vitronectin-coated glass, a multifunctional protein found in plasma, platelets, and the extracellular matrix, to ensure hESC viability. Cells were cultured for 21 days, and results showed that graphene promoted the expression of genes involved in gradual differentiation into mesodermal and endodermal lineage cells and subsequently into cardiomyocytes, compared to cultures on glass without graphene.

Conclusion: Graphene can provide a platform for developing stem cell therapies for heart diseases by enhancing the cardiomyogenic differentiation of human embryonic stem cells.

Tae-Jin Lee, et. al., Graphene enhances the cardiomyogenic differentiation of human embryonic stem cells, Biochem Biophys Res Commun, 2014, 452(1):174

2016- Impact on kidney function. The effect of intravenously administered graphene oxide (GO) on the kidneys of mice was studied. Results showed that GO was excreted through urine, indicating rapid transit through the glomerular filtration barrier (GFB) without nephrotoxicity. The analysis concluded an absence of kidney function impairment up to one month after GO injection at increasing doses. Histological examination found no damage to the glomerular and tubular regions of the kidneys. Ultrastructural analysis also revealed no damage or changes in podocyte slit size, endothelial cell fenestra, or glomerular basement membrane width. Endothelial and podocyte cultures restored their barrier function after >48 hours of GO exposure, with significant cellular uptake observed in both cell types after 24 hours.

Conclusion: GO is not toxic to the kidneys..

Dhifaf A. Jasim, et. al., The Effects of Extensive Glomerular Filtration of Thin Graphene Oxide Sheets on Kidney Physiology. ACS Nano 2016, 10, 12, 10753

2018- Effect on Neuronal Activation. The effect of monolayer graphene on neuronal activation was evaluated. It was identified that graphene modifies membrane-associated functions in cultured cells, meaning it adjusts the distribution of extracellular ions at the interface with neurons—a key regulator of neuronal excitability.

The observed membrane changes included stronger potassium ion currents and a shift in the fraction of neuronal activation phenotypes from adaptive to tonic activation. The study’s hypothesis suggested that graphene-ion interactions are maximized when single-layer graphene is deposited on electrically insulating substrates.

Conclusion: Graphene oxide can act as a substrate for neuronal interaction.

N. P. Pampaloni, et. al., Single-layer graphene modulates neuronal communication and augments membrane ion currents, Nat. Nanotechnol., 2018, 13, 755

2018- Adjuvant in the Proliferation of Pulmonary and Neuronal Cells. Graphene oxide “papers” of different sizes and thicknesses were fabricated as a substrate for the culture of human pulmonary and neuronal cells. Their capacity for cell adhesion and proliferation was evaluated, along with a possible cytotoxic response by detecting lactate dehydrogenase (LDH) in cell supernatants.

Conclusion: Graphene oxide can act as a biocompatible cellular substrate for cell growth without cytotoxic effects, opening greater possibilities for tissue engineering, regenerative medicine, and bionic applications.D. A. Jasim, et. al., Graphene-based papers as substrates for cell growth: Characterisation and impact on mammalian cells, FlatChem, 2018, 12, 17

2020- Biocompatibility of Graphene in Dental Materials. The biocompatibility of a graphene-containing restorative material and dental cement was studied on a mandibular defect in an animal model. Cytotoxicity was evaluated in vitro at 24 hours on human dental follicle stem cells and oral keratinocytes. In vivo studies were conducted seven weeks after implantation, including histological analysis of collected bone tissue, plasma biochemistry, oxidative stress assessment, and subchronic organ toxicity analysis.

The in vitro results showed that the materials did not induce toxicity in cells. In vivo, the animal models exhibited no symptoms of acute toxicity or local inflammation. No changes were detected in organ weights, and histological analysis revealed no alterations in liver or kidney tissues. Systemic toxicity of the materials in organs was not observed.

Conclusion: The study provides further evidence of the potential of graphene-based dental materials for bone regeneration and biocompatibility.

A. Dreanca, et. al., Systemic and Local Biocompatibility Assessment of Graphene Composite Dental Materials in Experimental Mandibular Bone Defect. Materials 2020, 13, 2511; doi:10.3390/ma13112511

2022- Risks of Graphene in Microplastics. The study was conducted on a composite of polyamide 6 or Nylon-6, a plastic commonly used in the automotive and sports industries, reinforced with reduced graphene oxide (rGO 2.5%). The material was then subjected to wear to emulate natural processes throughout its useful life, releasing particles approximately between 1.9 µm and 3.2 µm in size. To analyze the effects of the worn particles along the most likely exposure routes, in vitro human cell models of the lungs, gastrointestinal tract, skin, and immune system were used, as well as an animal model to study pulmonary exposure in vivo.

At the end of the study, only limited acute responses were found after exposure to the microplastics in the different models. Only the free rGO induced significant adverse effects, particularly in macrophages.

Conclusion: Microplastics with graphene suggest a low risk to human health. Graphene materials should not be inhaled.

S. Chortarea, et. al., Hazard assessment of abraded thermoplastic composites reinforced with reduced graphene oxide, Journal of Hazardous Materials 435 (2022) 129053.

2023- Pulmonary Function. The biological response, distribution, and biopersistence of four types of graphene in the lungs of mice were analyzed up to 28 days after a single oropharyngeal aspiration. The results showed that none of the materials induced a strong pulmonary immune response, with neutrophils being more effective at internalizing, degrading, and eliminating small graphene sheets (~50nm) than macrophages, as larger sheets (~8µm) may have greater persistence.

Conclusion: Graphene does not cause an inflammatory response in the lungs; however, it is important to consider the size of the sheets, as smaller ones are easier to eliminate from the airways and, therefore, safer.

Thomas Loret, et. al., Lung Persistence, Biodegradation, and Elimination of Graphene-Based Materials are Predominantly Size-Dependent and Mediated by Alveolar Phagocytes, Small, 2023,19(39): e2301201

2024- Pulmonary and Cardiovascular Function. An in vivo study was conducted to evaluate the effect of graphene oxide inhalation on pulmonary and cardiovascular function in healthy humans. For the trial, 14 volunteers inhaled small and ultrafine graphene oxide sheets at a controlled concentration during two-hour repeated visits. Heart rate, blood pressure, pulmonary function, and inflammatory markers were unaffected regardless of particle size; blood analysis showed few differential plasma proteins, and thrombus formation increased slightly in an ex vivo arterial injury model.

Conclusion: Graphene oxide inhalation can be tolerated and is not associated with apparent harmful effects in healthy humans. The study lays the groundwork for further human studies that examine a larger number of individuals as well as different types and doses of graphene.

Jack P. M. Andrews, First-in-human controlled inhalation of thin graphene oxide nanosheets to study acute cardiorespiratory responses. Nature nanotechonoly, 2024, 19, 705.

Biodegradation: Process by which a substance is broken down by living organisms through enzymatic or metabolic mechanisms

One of the most relevant aspects in evaluating the safety of graphene is its biodegradability. Research conducted under the Graphene Flagship project has demonstrated that graphene and graphene oxide can be successfully degraded, as follows:

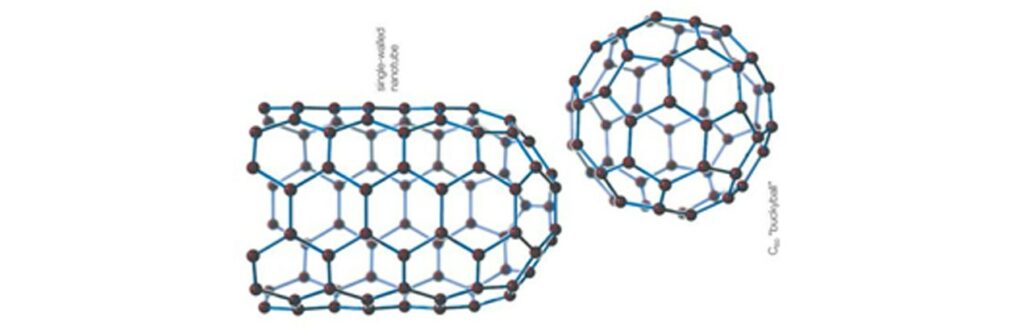

2018 – Researchers affiliated with the European Union’s Graphene Flagship project, from institutions such as the National Center for Scientific Research (CNRS) in France, the University of Strasbourg, the Karolinska Institute, and the University of Castilla-La Mancha (UCLM), through studies such as “Dispersibility-Dependent Biodegradation of Graphene Oxide by Myeloperoxidase” (2015), “Graphene Oxide is Degraded by Neutrophils and the Degradation Products Are Non-Genotoxic” (2018), and “Peroxidase Mimicking DNAzymes Degrade Graphene Oxide” (2018), discovered that the enzyme myeloperoxidase (MPO) successfully degrades both graphene and graphene oxide.

Myeloperoxidase (MPO): An enzyme released by neutrophils, cells responsible for eliminating any foreign body or bacteria entering the body, present in the lungs. When a foreign body or bacteria is detected, neutrophils surround it and secrete MPO to destroy the threat.

Professor Andrea C. Ferrari, Head of Science and Technology at Graphene Flagship and Chairman of its Management Panel, stated: “The report on a successful pathway for graphene biodegradation is a very important step in ensuring the safe use of this material in applications. The Graphene Flagship has placed research into the health and environmental effects of graphene at the center of its program from the beginning. These results strengthen our confidence in the potential of graphene for biomedical and technological innovations.”

Cristina Martın, et al., Biocompatibility and biodegradability of 2D materials: graphene and beyond, Chem. Commun., 2019, 55, 5540

This discovery is crucial, as it confirms that graphene is not an accumulative material in the human body or the environment. Instead, it can be naturally processed and eliminated, reducing the risks of long-term toxicity.

Conclusion

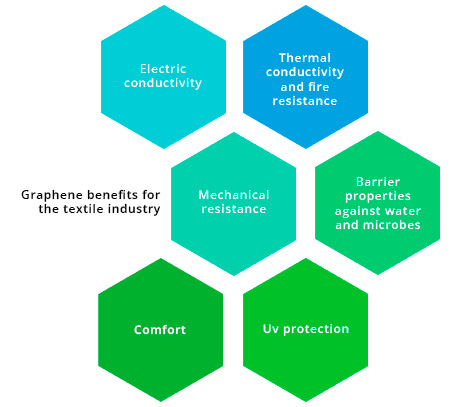

Graphene and its derivatives have demonstrated a high degree of biocompatibility and controlled degradability in various scientific studies. While challenges remain, current evidence supports its safety in biomedical, industrial, and environmental applications.

The key to its proper use lies in selecting the right type of graphene and its functionalization, which helps minimize risks and enhance its benefits. Thanks to advances in research, the viability of graphene as an innovative, safe, and sustainable material is becoming increasingly clear, with applications ranging from regenerative medicine to advanced nanotechnology.

The continuous development of scientific studies will further strengthen its position as one of the key technologies of the future, ensuring its responsible and effective implementation across different industries.

Authored by: EF/DHS