Graphene-reinforced lime paints:

the revolution in the construction industry

Although the exact date on which lime was discovered by man is not known, there are records dating back more than 14,000 years regarding its use. In the case of Mexico, it has been used since pre-Hispanic times both for construction and for nixtamalization, in ancient Greece it was used to color numerous frescoes (2800 B.C.- 1000 A.D.), the Chinese wall was built after stabilizing the soil with lime (500 AD) and among many other historical data, lime became popular in Europe during the Middle Ages for its disinfectant, breathable and fire-retardant properties, being used mainly as a coating on the exterior of houses and barracks. Subsequently, its implementation in the cities extended until the beginning of 1900 and it was not until the middle of that same century that it reached rural areas, a period in which synthetic paints gained ground over lime thanks to their ease of application, wide range of colors and low cost.

However, at the end of the 1970s and due to the awareness of the dangers of some synthetic paints with respect to health and the environmental pollution caused by certain components (heavy metals and volatile organic compounds [VOC]), lime paints once again had a boom as they are safer products and have a smaller footprint on the environment.

Among the benefits of lime-based paints or coatings are that they are 100% natural, ecological and VOC-free products, which absorb CO2 during their hardening process, which means that their use contributes to air purification. They are also breathable materials, that is, they allow the structures to “breathe” and do not concentrate moisture. In addition, they are thermoregulators, this means that they do not allow drastic changes in temperature in the buildings and, on the contrary, they help the buildings to stay cool.

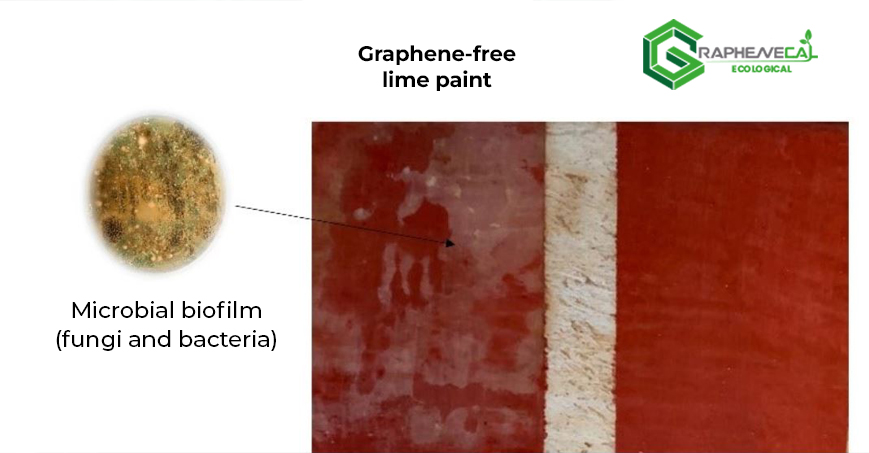

However, and despite their great advantages, one of the main drawbacks of lime-based paints is their high permeability and, therefore, poor resistance to humidity, which is in turn related to limited adherence that requires constant repair work. maintenance. On the other hand, and although antimicrobial or biocidal properties are attributed to lime, it is not convenient to ensure that all the products that contain it offer this protection, since they are materials susceptible to being attacked by microbial species such as Aspergillus spp., Cladosporium spp, Fusarium spp., Trichoderma spp., Actinobacteria and Bacteroidetes among other species responsible for its biodeterioration as well as some infections.

With the aim of contributing to a sustainable present and future, in 2022 the strategic alliance between the companies Energeia-Graphenemex® and Oxical®, after almost 2 years of research, launched a new coating made from modified high-purity lime with Graphene nanoparticles, under the Graphenecal® brand.

Graphenecal nanoengineering reaches the market to create a new generation of lime-based coatings that exceed the characteristics of water-based paints made from chemical resins. The nanometric network that generates the graphene nanoparticles in combination with the high-purity lime and other natural products used in its formulation, compacts and organizes its entire structure at the molecular level, offering greater durability to the coating and improving its characteristics, thanks to the perfect balance that exists between greater impermeability (>50-80%) with adequate breathability avoiding the accumulation of moisture on surfaces, coupled with the excellent benefits offered by its great antimicrobial capacity (>99.9%) that prevents the adhesion and formation of microbial biofilms not only to protect against the biodeterioration of structures but also as a tool in infection control, among other advantages such as excellent adhesion, covering power, resistance against the effects of weather, greater thermoregulation, CO2 capture and lower carbon footprint in comparison with other products, no need for chemical additives, biocide products or contaminants, placing Mexico at the vangard in the development of environmentally friendly products.

Greater Impermeability

Representative image of the impermeability of Graphenecal on two different substrates.

Antimicrobial Capacity