Polymeric Graphene Oxide Fibers:

an effective solution to prevent cracking in Concrete

Globally, concrete is the most used construction material. Concrete is applied in different infrastructures, including buildings, bridges, dams and tunnels, due to its high compressive strength. However, concrete has some limitations and problems, such as low tensile strength and cracking. Cracks or fissures can appear during the production of concrete and at subsequent stages. They begin as nanoscale cracks, later they join together forming micro and macro cracks. This behavior is closely associated with the hydration process that cement undergoes, where it releases heat and increases the temperature of the concrete. In large structures, heat cannot be released easily, causing expansion stresses, and thermal contraction, leading to cracking.

Because concrete is constantly exposed to impact, fatigue and other types of loads, cracks or fissures, and irreparable failures can occur, it is why it is common to reinforce it with polymer fibers to improve the physical-mechanical characteristics of concrete.

Incorporating fibers into concrete has proven to be effective in delaying or preventing crack propagation. At a commercial level, there is a wide range of polymeric fibers as three-dimensional secondary reinforcement of concrete and mortar, with different lengths and sizes (macrofibers and microfibers). These polymer fibers are made from materials such as polypropylene (PP), high-density polyethylene (HDPE), PVA and polyester.

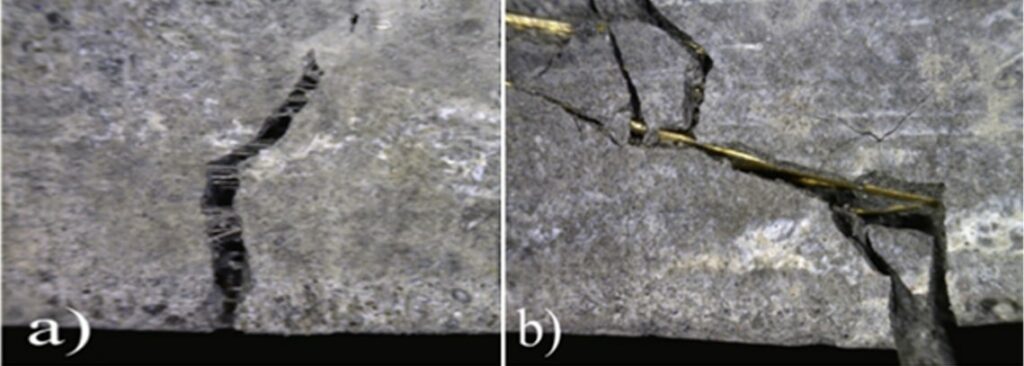

However, there are some disadvantages or limitations of commercial polymer fibers, the hydrophobic nature of polymer fibers, or/and its elastic modulus is insufficient, so the incorporation of polymer fibers in concrete only slightly improves the resistance to the tension. Furthermore, the little improvement in tensile strength is mainly attributed to insufficient bond strength at the interface between the fiber and matrix, i.e., low compatibility (no adequate anchorage) of the fiber with the concrete. So the fibers easily detach from the concrete, increasing the risk of cracking and failure in the concrete. (See Figure 1)

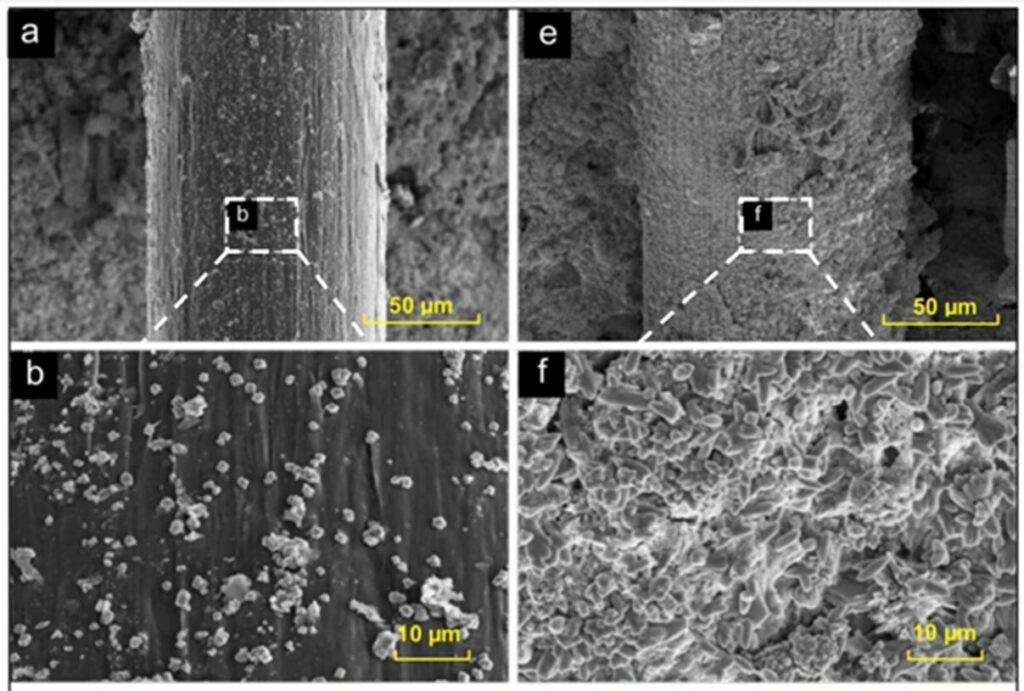

Currently Energeia Fusión- Graphenemex, under its Graphenergy Construction line, developed polymeric macrofibers with graphene oxide (GO). Graphene oxide is a nanomaterial, which due to its unique physical and chemical characteristics, such as its large surface area (736.6 m2/g), extraordinary mechanical properties (25 GPa), thermal properties and its unique structure with multiple oxygen-containing groups on its surface, makes GO an ideal material for modifying the surface of polymer fibers. These characteristics allow improving the interface or compatibility of the fibers with cementitious materials and/or concrete.

The oxygenated groups of GO act as anchoring sites for the formation of cement hydration products, improving the interface between the fibers and the cementitious matrix (See Figure 2). Consequently, a stronger interface leads to an improvement in the tensile strength of the concrete.

PVA/GO fiber (e and f). Taken from [Ref. 2]

When a concrete structure is subjected to loading, tension and compression stresses begin to build up. Over time, small cracks appear in places where the stress reaches a critical point. In this sense, the Graphenergy reinforcing fibers remain solidly anchored in the concrete matrix and absorb the tensile stress at any point and direction.

If there is a small crack the fibers are held firmly within the concrete, as the tension increases the fiber slowly elongates (deforms) until it reaches its maximum strength. With a 38% improvement in tensile strength and 29% more elongation than commercial reinforcement, concrete structures reinforced with Graphenergy fibers can withstand high bending stress over a long period. These nanotechnology fibers delay the appearance of the first crack and slow down the spread of cracks in the concrete.

The main difference between Graphenergy reinforcing fibers and other commercial fibers is that fibers with graphene become part of the concrete matrix and give rise to a composite material. Graphenergy reinforcing fibers form a reinforcing network throughout the structure, reducing or inhibiting the appearance of cracks (effective crack control), and improve the ductility of concrete. Additionally, Graphenergy reinforcing fibers improve concrete quality, providing greater shrinkage resistance, fire resistance and greater impermeability in concrete.

References

- Filho, A., Parveen, S., Rana, S., Vanderlei, R., & Fangueiro, R. (2020). Mechanical and micro-structural investigation of multi-scale cementitious composites developed using sisal fibres and microcrystalline cellulose. Industrial Crops and Products, 158, 112912.

- Yao, X., Shamsaei, E., Chen, S., Zhang, Q. H., de Souza, F. B., Sagoe-Crentsil, K., & Duan, W. (2019). Graphene oxide-coated Poly(vinyl alcohol) fibers for enhanced fiber-reinforced cementitious composites. Composites Part B: Engineering, 107010.

- Lingbo Yu, Shuai Bai, Xinchun Guan, Effect of multi-scale reinforcement on fracture property of ultra-high performance concrete, Construction and Building Materials, Volume 397, 2023, 132383, ISSN 0950-0618.

- Chen Lin, Terje Kanstad, Stefan Jacobsen, Guomin Ji, Bonding property between fiber and cementitious matrix: A critical review, Construction and Building Materials, Volume 378, 2023, 131169, ISSN 0950-0618.

- Bolat, H., Şimşek, O., Çullu, M., Durmuş, G., & Can, Ö. (2014). The effects of macro synthetic fiber reinforcement use on physical and mechanical properties of concrete. Composites Part B: Engineering, 61, 191–198.