Textile Innovations:

Exploring Graphene Trends in the Industry

Part I

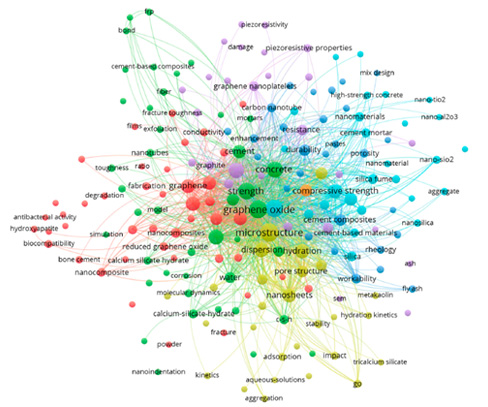

Graphene, a two-dimensional nanomaterial made of carbon atoms, is revolutionizing materials science and nanotechnology. It stands as the only known material that combines a myriad of thermal, electrical, mechanical, optical, and other properties. Moreover, it can integrate with other structures, sharing and significantly enhancing their original characteristics. Since its isolation in 2004, researchers and industries worldwide have sought to leverage its extraordinary benefits. However, high production costs and challenges in obtaining sufficient quantities for industrial applications have hindered widespread market adoption.

Despite these challenges, the textile industry has not remained idle in the face of the opportunities presented by graphene nanotechnology. Over the last decade, it has explored not only graphene but also other nanomaterials like copper nanoparticles (CuNp’s), silver (AgNp’s), gold (AuNp’s), zinc oxide (ZnO), titanium dioxide (TiO2), and carbon nanotubes, among others. The goal is to imbue textiles with antimicrobial properties, flame retardancy, mechanical strength, electrical conductivity, and various other attributes. The key difference lies in graphene’s multifunctional capabilities; it can provide or enhance more than one benefit simultaneously.

What Benefits Does Graphene Offer in the Textile Industry?

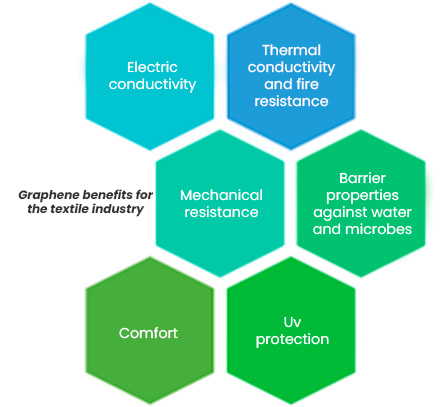

Graphene boasts an extensive and complex list of properties, ranging from mechanical to barrier-related, making it highly attractive for numerous applications. In the textile industry, initial interest focused on its electrical and thermal conductivity. However, extensive research has unveiled a wide array of benefits correlating with its multifunctionality.

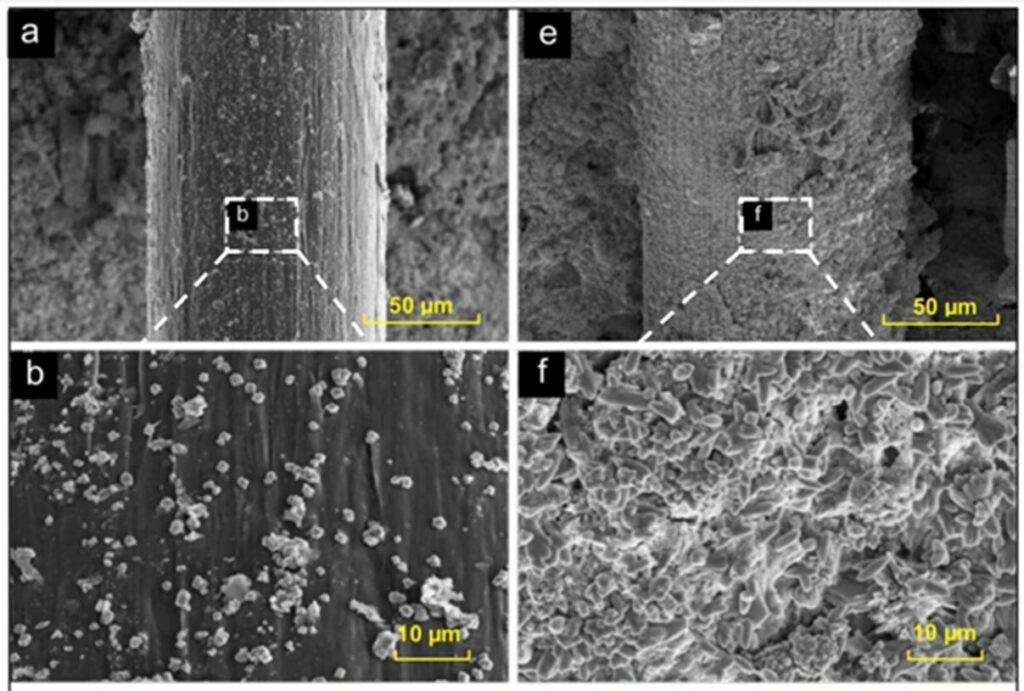

It’s crucial to note that the extraordinary characteristics of graphene, as described in the literature, often pertain to measurements conducted on nanomaterials in their pure form. To truly capitalize on their benefits in tangible applications, it’s necessary to combine them with three-dimensional materials capable of transferring their properties. Polymeric matrices have proven highly efficient as a support for graphene materials, with interfaces that are strong and stable facilitating superior property transfer.

How Does Graphene Interact with Textile Materials?

At the nanoscale, interaction mechanisms depend on multiple factors and generally involve electrostatic interactions, Van der Waals forces, hydrogen bonding, π-π interactions, or hydrophobic interactions. On the macroscale, understanding this interaction is contingent on the type of graphene, textile material, and the integration method or timing. The latter is particularly crucial because having the right graphene is not sufficient; anchoring and permanence throughout the structure of natural or synthetic textile fibers are variables that increase complexity.

In many cases, additional chemical modifications to graphene are necessary, and the implementation of other additives for charge modification is considered. Various technologies, such as vacuum infiltration, pressing, or dyeing methods, may be employed to improve interaction. However, these methods may be superficial, and achieving mechanical or flame-retardant benefits may require further chemical modifications or the use of specific technologies.

Due to the breadth of the topic, this article is divided into two sections. In this first part, we will discuss the uses of electrical, thermal (fire resistance), and mechanical properties of graphene in textiles. The next publication will conclude the description of barrier properties, protection against UV radiation, and comfort.

Electrical Conductivity

Graphene’s high electrical conductivity is fascinating for manufacturing smart textiles incorporating sensors, microprocessors, light indicators, fiber optics, etc. Applications extend to textiles with electromagnetic and antistatic protection, with potential uses in industries like oil, mining, military, and medicine. Graphene’s corrosion-free, lightweight, and flexible nature sets it apart from metallic fibers.

Studies have explored incorporating digital or electronic components into garments, such as glucose monitors, heart rate monitors, gas sensors, tension and torsion monitors, motion sensors, acoustic sensors, pulse sensors, or even solar energy harvesting.

Thermal Conductivity

Graphene’s well-known thermal conductivity benefits the rapid dissipation of heat in various materials, including textiles. Its integration into viscoelastic materials for mattresses or textiles used in summer garments helps maintain thermal balance associated with comfort and rest. Therapeutic applications are also being studied to stimulate blood circulation and aid muscle recovery from fatigue.

Graphene textiles have been used as heating elements in industrial and residential heating components such as carpets, car seats, and de-icing systems for aircraft access routes. Graphene, being corrosion-free and allowing for lower weight, offers additional advantages over metallic heating elements.

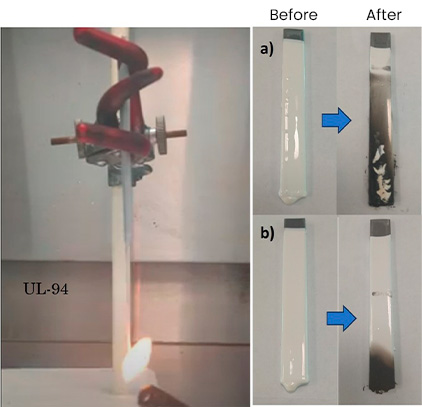

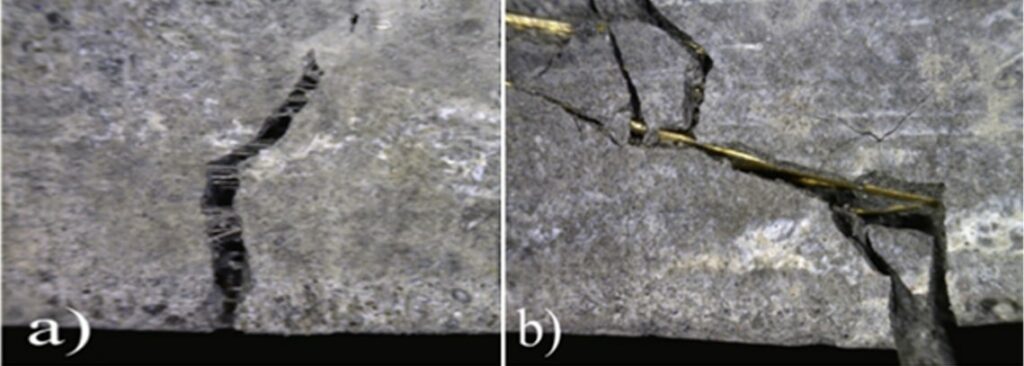

Fire Resistance

The thermal stability of graphene materials depends on their chemical structure and can range from 500°C to 3000°C. However, these conditions may vary when functionalized or combined with other materials. In certain cases, graphene can increase the decomposition temperature and ignition time. Graphene acts as a gas barrier due to its tortuous internal structure, reducing the diffusion of combustible gas to the flame source, inhibiting oxygen diffusion, delaying initial combustion, and preventing re-ignition. Graphene improves the thermal stability of polymers by decreasing the heat release rate, preventing fire spread, and reducing ignition time.

While some polymers with graphene may accelerate ignition time, once a carbon layer forms, it covers the polymer’s external surface and protects the sublayer from fire spread. Graphene’s chemical composition is free of halogens, eliminating the release of furans and dioxins that cause environmental issues.

At Energeia-Graphenemex®, leaders in Latin America in graphene production and development, we believe in the tremendous potential of this material to meet the needs of industrial sectors such as the textile industry. We are also aware of the scientific, technical, economic, and ethical needs inherent in each project. As a strategic ally, we collaborate with companies interested in innovating and improving their products and processes by forming multidisciplinary teams to pave the way for the introduction of new technologies like graphene into the market. We look forward to soon seeing the first graphene textiles in Mexico.

Redaction: EF/DH

References:

- Graphene Modified Multifunctional Personal Protective Clothing. Adv. Mater. Interfaces 2019, 6, 1900622;

- Graphene-based fabrics and their applications: a review. RSC Advances. 2016, 6:68261;

- Fabrication of a graphene coated nonwoven textile for industrial applications. Australian Institute for Innovative Materials – Papers. 2016, 2173;

- New Perspectives on Graphene/ Polymer Fibers and Fabrics for Smart Textiles: The Relevance of the Polymer/Graphene Interphase. Front. Mater. 2018, 5:18;

- Graphene applied textile materials for wearable e-textile. 5 th International Istanbul Textile Congress 2015: Innovative Technologies Inspire to Innovate‖ September 11th -12th 2015 Istanbul, Turkey;

- The Effect of Graphene Oxide on Flame Retardancy of Polypropylene and Polystyrene. Materials Performance and Characterization 2020, 9, 1, 284;

- Engineering Graphene Flakes for Wearable Textile Sensors via Highly Scalable and Ultrafast Yarn Dyeing Technique. ACS Nano 2019, 13, 4, 3847;

- Highly Conductive, Scalable, and Machine Washable Graphene-Based E-Textiles for Multifunctional Wearable Electronic Applications. Adv. Funct. Mater. 2020, 30, 2000293;

- Moisture- Resilient graphene – dyed wool fabric for strain sensing. ACS App. Mater. Interfaces. 2020, 12, 11,13265;

- Creating Smart and Functional Textile Materials with Graphene. Nanomaterials and Nanotechnology Biomedical, Environmental, and Industrial Applications. 2021, Chapter 13.;

- Graphene oxide incorporated waste wool/PAN hybrid fibres. Sci Rep 2021, 11, 12068;

- Moisture-Resilient Graphene-Dyed Wool Fabric for Strain Sensing. ACS Applied Materials & Interfaces 2020, 12, 11, 13265;

- Thermal Degradation and Flame-Retardant Mechanism of the Rigid Polyurethane Foam Including Functionalized Graphene Oxide. Polymers 2019, 11, 78;

- Tuning sound absorbing properties of open cell polyurethane foam by impregnating graphene oxide. App Acoustics. 151, 2019, 10;

- Intumescent flame-retardant polyurethane/reduced graphene oxide composites with improved mechanical, thermal, and barrier properties. Journal of Materials Science. 2014, 49, 243;

- Production and characterization of Graphene Nanoplatelet-based ink for smart textile strain sensors via screen printing technique. Materials & Design. 198, 15 2021, 109306;

- Caracterización de un tejido mezcla poliéster/ algodón aplicando grafeno mediante el proceso de adsorción. Tesis 2020;

- Síntesis y formulación de nuevas espumas de poliuretano flexibles con propiedades mejoradas. Tesis 2018.